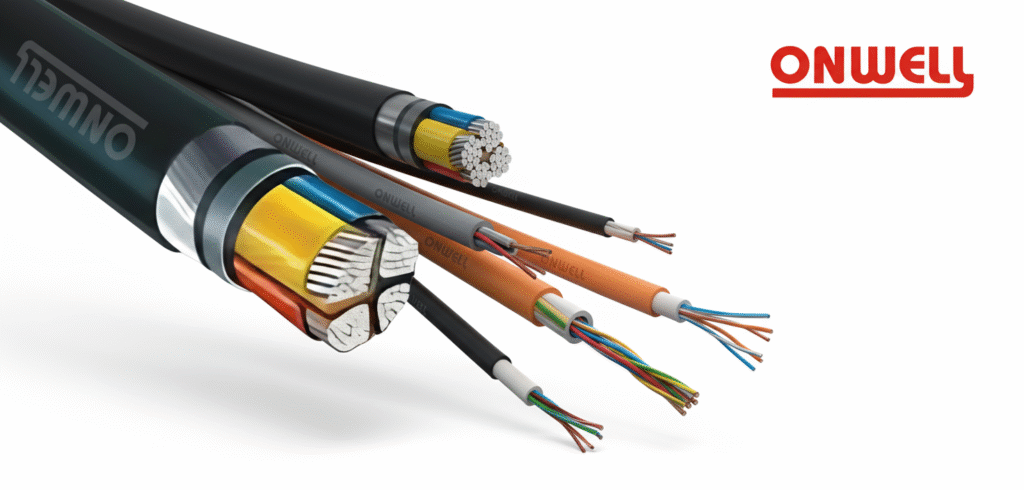

Onwell® Product Portfolio

Product Types & Features

FR (Flame Retardant) Wires & Cables

Insulated with fire-retardant PVC compound. The in-house formulation limits fire spread and maintains insulation integrity under high stress.

FR-LSH (Flame Retardant, Low Smoke & Halogen)

Designed to minimize toxic emissions and smoke in enclosed or crowded environments (hospitals, malls, high-rises).

HR-FR (Heat-Resistant, Flame Retardant)

Suited for industrial conditions where ambient temperatures are high. Can endure elevated thermal stress while preserving insulation.

ZHLS-FR (Zero Halogen Low Smoke + Flame Retardant)

Advanced polymer materials produce negligible halogen gas emissions and low smoke under fire. Ideal for critical infrastructure, tunnels, and public buildings.

PVC-XLPE / LT Cables

Flexible for general usage; built to national IS standards.

Submersible & Instrumentation Cables

Specialized designs for underwater or instrumentation settings where insulation and shielding are critical.

Elastomer Insulated Cables (up to 1100V)

Designed as per IS 9968, these cables are insulated with high-grade elastomer compounds such as EP Rubber, NBR offering superior flexibility, heat resistance, and mechanical strength. Ideal for dynamic and demanding applications where cables are exposed to vibration, movement, or varying environmental conditions.

Technical Specs & Construction

Voltage Grade

Conductor Material

Core Color Coding

Sheath

Insulation

Tolerance & Standards

Aluminum Strips

Our aluminium strips and conductors are precision-crafted for cable armoring, shielding, and power transmission, as well as for use in busbars and other industrial applications.